Manufacture introduction support

Our manufacturing management experts propose business improvement models.

We will help you solve your problems.

Otsuchi Town, Iwate Prefecture/N Co., Ltd. Head Office Manufacture

| Completion: | July 2012 |

| location: | Otsuchi Town, Kamikei District, Iwate Prefecture |

| overview: | Building area: approximately 210 tsubo, total floor area: approximately 420 tsubo, 2-story steel frame building |

| Business details: | Manufacture and sale of frozen seafood foods |

| Features: | HACCP compliant Manufacture Introduced high freshness maintenance freezer Proton freezer The first newly built factory in Otsuchi town after the earthquake |

Episodes during the construction period

- The construction period was only three months, and temporary accommodations were constructed near the site.

- Due to rising construction costs, only a factory was built. Unable to construct a cold storage facility, container freezers were used.

- Construction began after the earthquake with no residents living in the surrounding area and no water or sewage system in place.

- Four wells were dug, but they were unusable due to salt contamination.Secured from an old well 250m away.

- The septic tank was installed semi-underground due to high seawater level caused by ground subsidence.

- Construction began without water and electricity during the construction.

Contents of proposal

Proposal for “HACCP compatible factory”

What is HACCP?

It is a method of sanitation management that ensures product safety by analyzing in advance hazards such as microbial contamination that may occur at any stage of the food manufacturing and processing process, determining critical control points based on the results of the analysis to determine what measures should be taken at what stage of the manufacturing process to obtain safer products, and continuously monitoring these critical control points. This is a method of sanitation control that ensures product safety through continuous monitoring. Compared to conventional hygiene control based on sampling inspections, this method is more effective in preventing the shipment of problematic products, and also makes it easier to track down the cause of the problem.

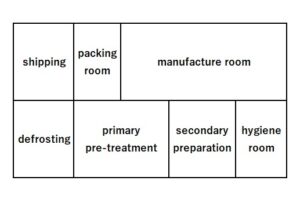

1F layout diagram

Incoming raw materials: Thawing

- Insect infiltration countermeasures from exterior walls: High-speed shutters

- Water leakage: Painted floor (color), hip wall (rust)

- Moisture: Ventilation measures

Pretreatment process

- Routes for food waste removal and storage

- Floor drainage system, sterilization process

- Low-temperature air conditioning, illumination of workers’ hands

manufacturing room

- Seasoning and heating. Flouring.

- Ventilation and condensation control for floor color classification, voile, etc.

- Dust collection countermeasures, ensuring illumination of workers’ hands

Pretreatment process

- Temperature control of frozen products: Low-temperature air conditioning

- Painted floor finish smoothness, illumination in inspection

- Consideration of dust control for cardboard boxes, etc., and pre-shipment rooms