Product business

PRODUCTProduct

business

“A food machinery manufacturer that works together with our customers”

Proton freezers, proton thawers, and other food equipment

We are the only company in Japan that has both freezing and thawing technologies.

We are the only company in Japan that possesses both freezing and thawing technologies.

Engineering to pursue and analyze “physics

As a group of professional engineers

and create technologies that are highly needed by society.

We create technologies that are highly needed by society.

Partnerships that build trust

We will fully demonstrate our individuality, skills, and abilities,

We aim to earn the trust of our customers as a partner that can realize prosperity together with them.

We aim to earn the trust of our clients as a partner that can achieve prosperity together with them,

We will provide you with attentive services.

Enhancement of services in terms of both hardware and software

In addition to the accumulation of test experiment results from users,

in the past, we have made full use of proton-freezing products

French restaurant operations,

In the past, we have operated our own food manufacturing plants in Japan, China

and food manufacturing factories in Japan, China, and Southeast Asia,

Proton-freezed food products and gifts, as well as a network of

network among proton users (fresh network).

(Fresh Network) among proton users, etc,

We are also trying to build a network (Fresh Network) among Proton users.

We are also trying to establish a network among Proton users (Fresh Network).

Food in the 21st Century,Diversified Business Collaboration

By “unifying the vision and purpose” of each industry’s business activities

By “unifying vision and purpose

By “unifying the vision and objectives” of each industry, the management resources of each member can be fully utilized,

The synergistic effect will create new businesses and increase business revenues.

and increase business revenues through synergy.

“Using a proton freezer…”

Faster and higher quality freezing than conventional freezing!

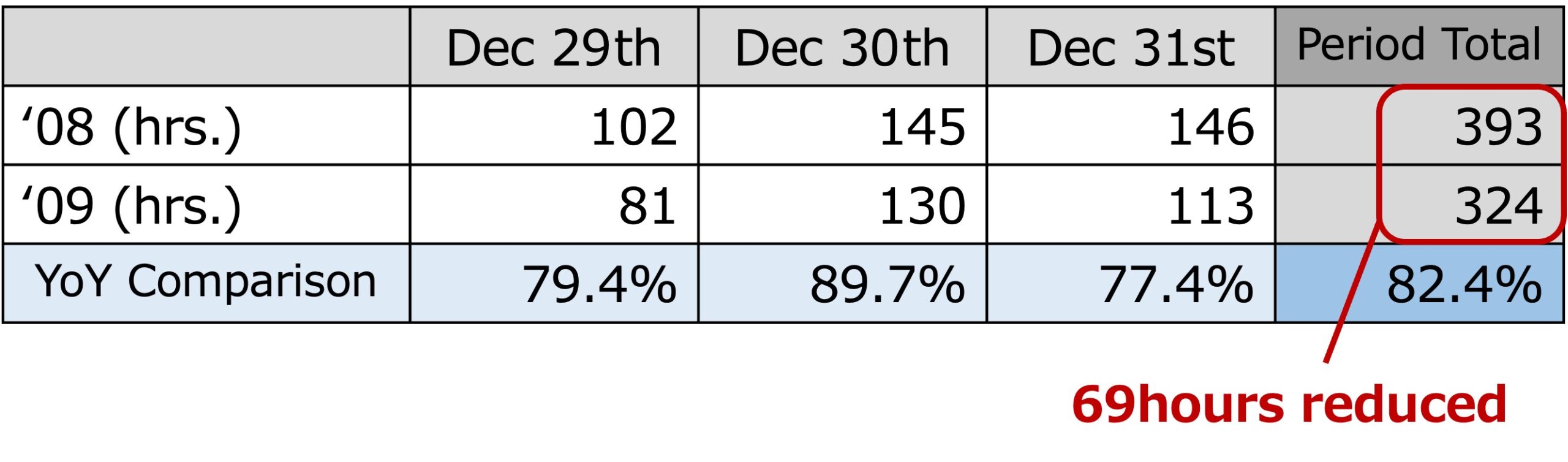

Compared with conventional quick freezing and our thawing machine, we have realized an energy-saving model that reduces time!

Our planners, experts in production management, will propose a model for business improvement.

- Decrease in the number of items manufactured per day

- Reduction of work and space for purchasing and stocking materials and supplies

- Reduced work processes

- Reduction of item switching time

- Increase in man-hour volume and man-hour value of production

- Decrease in working hours

- Enabling the introduction of a 2-day workweek

3. ECO improvement

- Reduction of material loss

- Careful and hygienic manufacturing.

- Occupancy also increased (to 70-80%)

- New Product Development

- Now able to handle small-lot orders and other items that could not be ordered in the past

- Capable of handling excess production capacity due to decentralized manufacturing

- Manufacture and sale of additive-free products